Construction Product Range

Geo-Proof Multi Application Waterproofing Membrane | Anchor Grip Basement Waterproofing Membrane | Dimple Sheet Protection for Basement Waterproofing Membrane | Dimple Drain Sheet - Water Drain System for Landscape Garden Area | GTP-HDPE Sand Coated Membrane for Basement & Foundation Waterproofing | LAM-PLAST Concrete formwork board

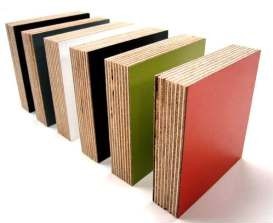

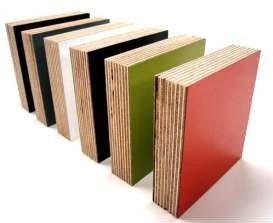

LAM-PLAST CONCRETE FORMWORK BOARD

WHAT IS LAM-PLAST FORMWORK BOARD?

The plastic sheet-laminated shuttering plywood represents a novel and environmentally friendly building material, surpassing traditional shuttering plywood formwork. This advanced generation product features a Lamm-Plast composite plastic sheet securely bonded to the surface of the plywood board. When utilized with precision, it can achieve increased repetition cycles, providing a smooth finish to concrete. This not only reduces costs but also enhances the overall quality of the construction work. Combining the inherent qualities of wooden formwork with the advantages of plastic formwork, it emerges as an ideal formwork board.

PRODUCT SPECIFICATION

- Thickness: 10mm, 12mm, 18mm

- Width: 1220 mm (4 feet)

- Roll Length: 2440 mm (8 feet)

- Surface Finish: Matt / Glossy Finished

- Colour: Green, Red, Yellow or Customized

- Material: Water resistance plywood core laminated with thick composite plastic sheet

TECHNICAL SPECIFICATIONS

- Weight: 30 – 32 kg (12 mm x 4 x 8 ft.)

- Weight: 38 – 40 kg (18 mm x 4 x 8 ft.)

- Flexural Strength: > 7000 N/mm2

- Used Carefully to get more repetition

- Water Resistant: Excellent

- Dimensional Tolerance : Thickness ± 5 mm, Length and Width± 3.0 mm

- High-grade Phenol bonded water resistance plywood sheet matching to IS 710 and IS

- Laminated both side with strongly bonded with durable, water resistance plastic laminated

APPLICATION AREA

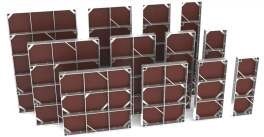

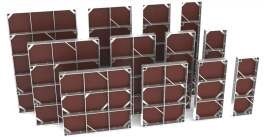

- Specifically used for all forms of concrete formwork, including walls, beams, columns, and slabs, in

- Utilised in all types of specialised RCC buildings that call for high levels of accuracy and

- Utilised in a variety of modular formwork applications with frames made of aluminium, steel, GI, and other

- Used in various applications where high repetition needs exist, such as the manufacture of concrete block building pellets, among many

ADVANTAGES

- Capable of being utilized up to 25 times.

- Strong and Durable

- Good capacity for screws and nails holding

- Termite, rot, and fungus resistant

- Several repetitive uses are possible with careful

- Low expansion and contraction coefficient

- High water resistane

- User-friendly and convenient to use

- Similar to regular plywood, it can be cut, nailed, and

- It provides concrete with a polished, smooth surface

- Overall, the Lamm-Plast formwork boards are fairly affordable

Product Gallery for Concrete Formwork Board

Previous

Next